Supply chain risk management (SCRM) involves identifying, assessing, and prioritizing supply chain risks. It helps companies develop strategies to enhance resilience and mitigate threats from suppliers, manufacturers, and logistics.

Tech companies face growing demands for new technology and innovation. Supply chain disruptions can cause delays that frustrate consumers and put companies behind their competitors.

The recent deluge of calamities and regional conflicts has also impacted supply networks worldwide. Recent restrictions on the Panama Canal and reduced traffic on the Suez Canal have further crippled supply lines. A solid SCRM plan ensures tech companies can quickly adapt to changes and recover from these interruptions.

- Unique Challenges in Tech Industry Supply Chains

- Top Risks in Tech Supply Chain Management

- How to Identify and Assess Supply Chain Risks

- Enhancing Readiness for Supply Chain Risks

- Leveraging Technology for Supply Chain Risk Management

- Effective Strategies for Supply Chain Risk Management

- Emerging Trends in Supply Chain Risk Management

- Regulatory and Compliance Challenges in Tech Supply Chains

Unique Challenges in Tech Industry Supply Chains

Tech companies have to deal with multiple hurdles in supply chain management:

-

Complexity and Global Reach

Tech supply chains are intricate and globally interconnected. For instance, semiconductors are made from raw materials like silicon. These are sourced from one country, made into chips in another, and assembled into the final product elsewhere. Therefore, disruptions in one region can have widespread ripple effects, as exemplified by the COVID-19 pandemic and the Russo-Ukrainian War.

Governments are increasingly implementing policies to safeguard their national interests. This only adds another layer of complexity and uncertainty to global supply chains.

-

Rapid Technological Advancements

Rapid strides in technology create both opportunities and challenges for supply networks. Case in point: digitization and automation. They enhance supply chain efficiency and transparency. However, they also require continuous updates and integration to keep systems compatible.

This risk is called obsolescence. As new technologies emerge, older systems and processes quickly become outdated. If they are not promptly upgraded or replaced, this can lead to potential disturbances in the supply chains. This is frequently seen in IT and consumer electronics.

Top Supply Chain Management Risks in the Tech Industry

Some of the most pressing risks in technological supply chains include:

-

Labor Shortage

A shortage of skilled workers can lead to slower production rates and increased costs. A decrease in workers in key logistics roles, such as truck drivers and warehouse workers, can also lead to delays in the delivery of components and finished products.

During the COVID-19 pandemic, the growth of e-commerce drove demand for logistics workers. The supply of workers did not keep pace, however, causing shortages and delays. As a result, companies have turned to automation, increasing worker retention by providing work-life balance and more growth opportunities.

-

Natural Disaster Risk

Events such as earthquakes, floods, and hurricanes can damage infrastructure, halt manufacturing, and delay shipments. It comes as no surprise that the 2011 earthquake and tsunami resulted in a severe disruption in the supply chains of hi-tech companies and the car industry. About 22% of the world’s supply of 300 mm silicon wafers came from Fukushima Prefecture, and 60% of critical auto parts production was in the same area.

-

Difficulty Estimating Demand

Rapid technological advancements, short product life cycles, and fluctuating consumer tastes all make forecasting demand challenging. This can result in overproduction or stockouts, which are costly for companies.

Tech companies are turning to machine learning and data analytics to analyze vast amounts of data and accurately predict future demands. Additionally, having open lines with suppliers and customers helps align production with market demands.

-

Cybersecurity

Due to the high value of the data and intellectual property involved, cybersecurity risks are critical in tech supply chains. Cyberattacks can lead to data breaches and operational setbacks, causing significant financial losses.

In April 2024, a supply chain attack on business analytics software company Sisense possibly exposed its customers’ credentials and gave access to Sisense clients, including big companies in finance, retail, media, and technology.

(Also Read: Future Impact of Technology on Supply Chain Management)

Strategies to Identify and Assess Supply Chain Risks

There are several strategies to manage supply chain risks:

-

Risk Mapping and Assessment

Supply chain risk mapping is the process of visualizing the entire supply chain to identify, assess, and prioritize vulnerable points and potential disruptions. It includes the following steps:

- Gather data on all supply chain elements, including material sources, production lines, packaging, and distribution. This also includes supplier locations, practices, and risk management strategies.

- Analyze and categorize risks based on their likelihood and impact.

- Some risks can’t be predicted. Use the risk map to identify and monitor vulnerable areas.

- Regularly audit and inspect the supply chain to assess and reduce risks. This helps identify and resolve internal risks, compliance issues, and structural weaknesses.

Use tools like risk matrices to plot the likelihood and impact of risks. ESG risk monitors to identify threats related to environmental, social, and governance factors.

-

Supplier Audits and Assessments

Regular supplier audits give information on suppliers’ operations, quality control, and compliance with regulatory requirements. Here’s how you can conduct one effectively:

- Establish clear standards and criteria for audits.

- Gather detailed information on the supplier’s operations.

- Conduct onsite visits to verify information and observe a supplier’s operations.

- Seek feedback from suppliers’ employees regarding working conditions and practices.

- Implement corrective actions and improvement plans based on your findings.

Increasing Supply Chain Risk Readiness

A stable supply chain requires a comprehensive contingency plan and adaptable supply networks.

-

Developing Contingency Plans

A flexible contingency plan lets you respond quickly to unforeseen events, minimizing disruptions. Rigid plans can become obsolete if they don’t adapt to market changes or new risks. Here are steps you can follow when developing contingency plans:

- Identify and assess potential risks, like natural disasters and geopolitical events, and rank them by severity and likelihood.

- Develop response strategies with a communication plan, alternative suppliers, and resource allocation protocols. Assign roles and ensure everyone is aware of the measures.

- Regularly test and update plans, conducting drills and simulations to ensure team readiness.

-

Building Resilient Supply Chains

Companies can enhance supply chain resilience with several strategies, including:

- Reshoring or nearshoring shortens supply chains, reducing risks from global shipping interruptions.

- Diversifying suppliers or sourcing from multiple regions minimizes reliance on a single source.

- Data analytics and forecasting enable proactive procurement, production, and logistics adjustments.

- Companies make use of inventory buffers or higher quantities of critical components.

- Real-time tracking and monitoring can improve supply chain visibility and allow for early detection of potential disruptions.

Toyota is a great example of a company that has successfully built resilient supply chains. As a result of the 2011 Tsunami, Toyota has now diversified its global suppliers and increased critical component stocks to handle semiconductor shortages and keep production running.

Utilizing Technology in SCRM

Addressing the many challenges in supply chain management requires the use of advanced technologies. Here are some key technologies that can help manage and reduce risks in supply chains.

-

Data Management Tools

Data management tools help by collecting and organizing information from different sources, giving a clear view of the entire supply chain. This visibility makes it easier to spot potential problems and respond quickly.

Data organization also helps automate routine tasks, saving time for managers to focus on more critical issues. Data silos often result in redundant and inconsistent data. Data management tools can remove this isolated data, allowing companies to work with the latest information.

-

Data Analytics

Data analytics tools take the organized data and use it to predict and prevent supply network interferences. For example, predictive analytics can alert a company to a possible machinery failure, giving them time to fix it before it becomes a bigger problem.

Prescriptive analytics goes a step further than just predicting problems. It also suggests the best ways to solve or avoid them. This helps businesses plan better and be ready for the unexpected.

-

Internet of Things (IoT)

The Internet of Things (IoT) uses smart devices like sensors and GPS trackers for real-time monitoring of the supply chain. These devices provide companies with up-to-date information on the condition and location of their goods, enabling quick responses to issues.

IoT sensors are frequently used to monitor servers in data centers. They ensure safe operation and alert technicians or automatically adjust settings to prevent overheating or other problems.

-

Artificial Intelligence (AI)

Artificial Intelligence (AI) predicts and manages risks by quickly analyzing large data sets. It optimizes logistics routes and improves demand forecasts. This can help inventory management, reducing stockouts and overstock. AI also automates tasks like screening resumes and planning employee training. This tackles labor shortages by speeding up hiring and ensuring staff are well-prepared.

-

Blockchain

Blockchain technology records all transactions on a secure, decentralized ledger. This makes it easy to verify product authenticity and origin, reducing fraud and costly errors. Blockchain can track the history of electronic components to ensure that only genuine parts are used. This prevents product failures from counterfeit parts.

Supply Chain Risk Appetite Statements

Risk appetite statements define the types and levels of risk an organization accepts to achieve its goals. In supply chain risk management, they specify acceptable risk levels in the supply chain. These statements guide leaders in making decisions that balance risk and reward while aligning with their objectives.

-

Transforming SCRM into a Value-Add

Risk appetite statements can transform SCRM from a reactive process into a proactive value-adding activity. This proactive approach allows companies to focus on areas with the highest potential impact. Additionally, it facilitates more effective resource allocation, ensuring that time, money, and personnel are directed toward managing the most significant risks.

For example, CISCO has a low tolerance for cybersecurity threats and zero tolerance for non-compliance with regulations, among others. The company prioritized sourcing from suppliers and regions that met its risk criteria, which helped it maintain continuity and reliability.

(Also Read: Blockchain Driven Supply Chain Innovations to Look for in 2024)

Implementing Effective Supply Chain Risk Management (SCRM) Strategies

Effective supply chain risk management is built on regular monitoring and strong supplier relationships.

-

Monitoring and Response Mechanisms

Monitoring involves the use of digital tools and analytics to oversee various supply chain nodes, from suppliers to transportation routes. This helps in recognizing leading indicators of risks, ensuring that companies can react swiftly to minimize their impact.

Operational risks are managed by maintaining inventory buffers, diversifying suppliers, and implementing robust logistics plans. Financial risks are mitigated with hedging strategies and insurance. Stringent cybersecurity protocols and regular audits protect against cyber threats. Contingency plans, like alternate sourcing and emergency response teams, reduce the impact of natural disasters.

-

Collaborating with Suppliers

A strong, cooperative relationship improves communication, transparency, and problem-solving. Maintain regular, open communication to keep all parties aware of supply chain risks and changes. Here are some tips to help build strong supplier relationships:

- Align objectives with suppliers to foster a partnership mindset.

- Implement and monitor KPIs to ensure suppliers meet standards and manage risks.

- Build trust through constant support.

- Use digital platforms for real-time data sharing and risk assessment.

Case Studies and Industry Examples

You can learn from two of the world’s leading tech companies: Apple and Samsung.

-

Success Stories

Apple conducts rigorous supplier audits to ensure quality, sustainability, and ethical compliance, mitigating risks related to supplier reliability and regulations. They use advanced demand forecasting and inventory management to prevent overproduction or understocking. To reduce regional disruptions, Apple has expanded manufacturing to Vietnam and India and is now considering Indonesia, decreasing its reliance on China.

-

Notable Failures

In a rush to compete with Apple, Samsung released the Note 7 without identifying battery defects from their suppliers. Poor quality control and a mishandled recall process led to similar issues in replacement units, damaging Samsung’s brand reputation.

Future Trends in Supply Chain Risk Management

Supply chains continuously encounter new opportunities from emerging technologies as well as threats from evolving risks.

-

Emerging Technologies

The latest innovation predicted to change supply chain management is 5G connectivity. The adoption of 5G will facilitate faster data transfer, improving communication and decision-making processes within the supply chain. It also has the potential to support automated vehicles or drones for delivery and warehouse management.

-

Evolving Risks

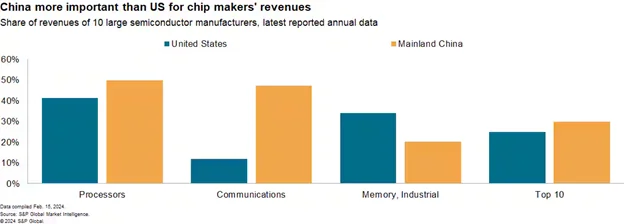

Changes in trade patterns due to geopolitical tensions are a threat companies must constantly watch out for. The ongoing rivalry between the U.S. and China has already shaken up supply chains across industries. Ten of the largest semiconductor companies rely on China for 30% of their revenue alone.

With these two countries racing against each other for technological dominance, the sector and the rest of the industry will have to battle changing regulations and supply routes. Because of this, diversification is now a necessity.

Cybersecurity threats are also becoming more sophisticated, forcing companies to adopt more robust security measures. Lastly, climate change has made natural disasters more unpredictable and destructive, posing a risk to the physical infrastructure of supply chains. Companies will now have to construct facilities to withstand these disasters better and develop plans to ensure the safety of their workers.

Regulatory and Compliance Issues in Tech Supply Chains

Companies must meet regulations and standards to operate globally. These can pertain to data privacy, product safety, environmental protection, and trade compliance. Navigating these requirements can be complex, as they vary by region and often change.

Companies need to stay informed about international laws and regulatory changes. To this end, they can consult with legal experts and regulatory consultants to ensure compliance with applicable laws.

Sustainability and Ethical Considerations in SCRM

Sustainability in supply chain management minimizes environmental impact and promotes long-term viability through practices like reducing carbon footprints, using renewable resources, and optimizing logistics. Companies can adopt technology to reduce energy consumption and emissions, minimize waste, and partner with sustainable entities.

Ethical practices ensure fair labor, transparency, and human rights through clear standards, audits, and open communication, ensuring fair treatment and safe conditions for workers.

Final Thoughts

The tech industry faces numerous challenges in managing supply chains, including evolving risks, regulatory complexities, and the need for sustainability and ethical practices. This can make SCRM daunting. However, innovative technologies and software provide valuable help.

Audit your current supply chain and secure your long-term success by anticipating and mitigating risks. Maintaining compliance and safeguarding your operations from nature’s forces, as well as cyberattacks, can help fortify your supply chains against future challenges.

Frequently Asked Questions about Supply Chain Risk Management

Q.What is software supply chain risk management?

A. Software supply chain risk management is the ability to identify, prioritize, and mitigate risks from components associated with third-party and first-party software and services.

Q. What is cyber supply chain risk management?

A. Cyber supply chain risk management focuses on protecting the supply chain from cyber threats by ensuring the security of hardware, software, and data throughout its lifecycle.

Q. How can tech companies address rising geopolitical tensions?

A. Tech companies can address rising geopolitical tensions by diversifying suppliers, establishing operations in stable regions, closely monitoring geopolitical events, and creating contingency plans with alternate sourcing and inventory strategies.